Composite Products

Keystone Engineering Company is a leader in the manufacture of high-strength and high-temperature composite materials. Ultra-high product quality is achieved through proprietary fabrication techniques and resin injection methods.

Composite Product Shapes

Fabricated composite material shapes include tubes and rods up to fifteen feet in length and various diameter sizes.

High-grade composite sheets are available in various sizes and thicknesses.

Unique material shapes are fabricated with our precise custom-made molds.

Composite materials can be machined to part design specifications by utilizing our precision in-house machine shop.

Composite Products and Fabrication Technologies

Lamination

We specialize in the fabrication of a superior epoxy laminate which approaches the maximum obtainable properties for a fiberglass reinforced material.

Our proprietary tube and rod fabrication technique ensure excellent resin wet-out, resulting in a composite product with consistent material resin content over 30%.

Our most popular laminate reinforcement material is fiberglass, typically E Glass or S Glass. We have the expertise to fabricate Carbon Fiber reinforced epoxy laminates.

Various fabric patterns are well-suited for different tool applications. Our engineers are able to provide material recommendations regarding your material needs.

High-quality, custom-made composites with unusual shape contours are fabricated by hand: integrating our high-temperature resistant, void-free resin systems and drape-able, high-tech reinforcement materials. Our innovative hand fabrication techniques have been practiced and improved since 1950.

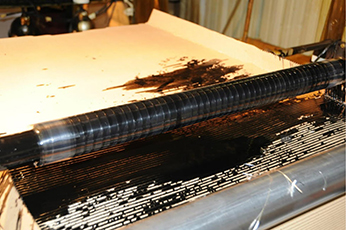

Filament Winding

Our four axis filament winder is capable of producing advanced composite materials with complex, custom-designed reinforcement patterns such as helical wind, zero angle wind, high angle wind, and bottle wind patterns. Composite parts up to fifteen feet in length and up to thirty inch diameters are wound with E-glass, S-glass, Kevlar, or Carbon Fiber reinforcement materials combined with our advanced resin systems.

Resin Injection

High temperatures are used with high pressures to inject resin into reinforcement material. Injected materials include: Epoxy, Fluorocarbon resin, Polycarbonates, Polyimides, Aromatic Polyether, and other high-performance material.