Technical Information

Composite Materials

Polymer Matrices Our advanced polymer matrices, Kemlox G and Kemlox HT-2, are designed for excellent performance at high-temperatures and high-pressures in a downhole environment. Our experts will be glad to discuss how our high-temperature resin systems can serve your needs.

Our Kemlox G material is used in downhole tools operating up to 350°F. Where higher temperature resistance is required, we recommend using our Kemlox HT-2 material. Kemlox HT-2 performs well at temperatures in excess of 400°F.

Custom matrix materials are readily available for achieving properties tailored to your specific material needs in higher temperature environments. Our experts will be glad to discuss custom matrix systems for any range of material requirements for a variety of environments.

Polymer Material Properties |

|||||

|---|---|---|---|---|---|

| Polymer Material Properties | Kemlox G | Kemlox HT-2 | |||

| Radio Frequency Transparent | |||||

| Electrically Insulating | |||||

| Good Machinability | |||||

| Chemically Resistant | |||||

| Strength at High Temperatures | Up to 350°F | Up to 400°F | |||

| Non-magnetic | |||||

Disclaimer: Data contained herein is based on tests conducted on representative samples, either from our own testing or from unconfirmed data supplied by vendors. Data is not intended for design specifications but for engineering consideration only. Information is subject to change. Keystone assumes no obligation or liability for any advice furnished by it or for the results obtained with respect to these products. It is suggested that the purchaser conduct tests to determine if these materials are suited to their applications.

Reinforcement Material

E-Glass

Our standard reinforcement is E-Glass. E-glass is a strong, radio frequency transparent fiberglass reinforcement.

S-Glass

Where higher strength is required, S-Glass reinforcement is used. Compared to E-Glass, S-Glass has higher strength properties, improved impact resistance, and improved radio frequency transparency.

Carbon Fiber

Carbon fiber is corrosive resistant, strong and lightweight reinforcement material. Compared to fiberglass, carbon fiber is stiffer, and has a higher strength to weight ratio.

Fiber Reinforcement Material Properties |

|||||

|---|---|---|---|---|---|

| Fiber Reinforcement Material Properties | E-Glass | S-Glass | AS4 Carbon | Kevlar ® 49 | Nextel™ 720 Ceramic |

| Tensile Strength (ksi) | 510 | 670 | 670 | 530 | 300 |

| Heat Resistance (Max Temp °F) | 1,300 | 1,600 | 6,300 | 800 | 2,200 |

| Density (kg/m^3) | 2,600 | 2,500 | 1,800 | 1,400 | 3,400 |

| Tensile Modulus (msi) | 11 | 12 | 34 | 16 | 28 |

| Break Elongation % | 4.8 | 5.4 | 1.6 | 2.4 | N/A |

| Coefficient of Thermal Expansion (10^-6/°F) | 1.6 | 1.7 | -0.1 | -2.7 | N/A |

| Radio Frequency Transparent | Yes | Yes | No | Yes* | No |

| Cost | Lowest | Low | High | High | High |

| Impact Resistance | Good | Good | Poor | Good | N/A |

| Chemical Resistance | Good | Good | Very Good | Poor | Good |

*Water absorption causes EM interference.

Disclaimer: Data contained herein is based on tests conducted on representative samples, either from our own testing or from unconfirmed data supplied by vendors. Data is not intended for design specifications but for engineering consideration only. Information is subject to change. Keystone assumes no obligation or liability for any advice furnished by it or for the results obtained with respect to these products. It is suggested that the purchaser conduct tests to determine if these materials are suited to their applications.

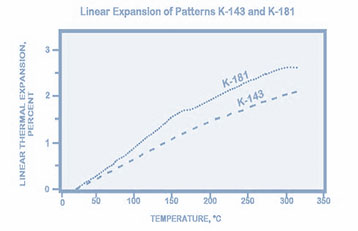

Fiberglass Laminate Reinforcement Patterns Our fiberglass laminate reinforcement patterns include K-143, and K-181.

- Pattern K-143 is a reinforcement material with about 80% of its reinforcement fibers orientated in the axial direction of the rod or tube. The K-143 pattern produces an epoxy laminate with very high tensile strength and is ideal for tubes and rods in tensile load.

- Pattern K-181 is a reinforcement material with approximately 50% of its reinforcement fibers oriented in both the axial and radial direction. It has higher burst and compressive strength than the K-143 pattern. The K-181 pattern is ideal for downhole tubes and thin-wall sections.

Linear Expansion of Pattern Materials vs. Temperature

Download PDF

Download PDF