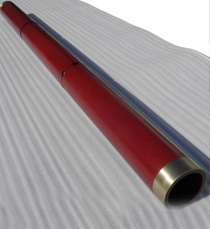

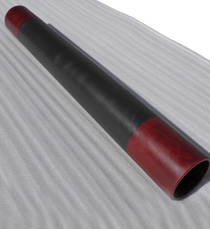

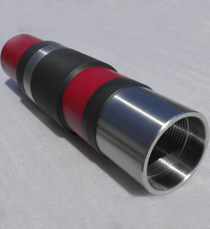

Turnkey Assembly

Our turnkey assembly services combine composite, rubber and metal material components with rigorous electrical, pressure, and temperature performance specifications.

Composite material fabrication, precision machine work, and product assembly are performed in-house.

We have proprietary adhesive techniques for metal-composite-rubber sealing using our void-free resin system. Rubber mandrel wrapping services may be performed in-house or outsourced to an approved vendor.

Outside Processes

We maintain an approved vendors list for all outside processes. Through our local network of vendors, Keystone ensures turnkey products requiring outside processes are delivered to customers on-time with the highest quality of workmanship.

Surface Treatments

We outsource surface treatments such as laser cladding for wear parts, shot peening of metals, phosphate coating, galvanizing, and plating of Nickel, Gold, and Silver.

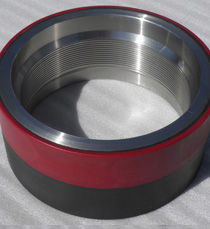

Rubber and Plastic Molding

We may outsource rubber mandrel wrapping services as well as conventional transfer, and compression molding of Neoprene, Nitriles, Fluoroelastomers, plastics, and proprietary rubber compounds for oil tool applications with high quality results. We also have the capabilities to perform these operations in-house.

Welding and Brazing

For critical hermetic welds that are Helium tight to 10-9cc/ sec, we utilize computer controlled Laser and an Electron Beam. These processes are provided by our affiliate company and used when assemblies call for close tolerances, dissimilar metals, or thin wall sections. Induction brazing and oven brazing are available. TIG and Plasma welding are used for non- critical applications.

Non Destructive Testing

Composite materials are tested for defects using non-destructive testing techniques at an outside vendor.